Production Machining

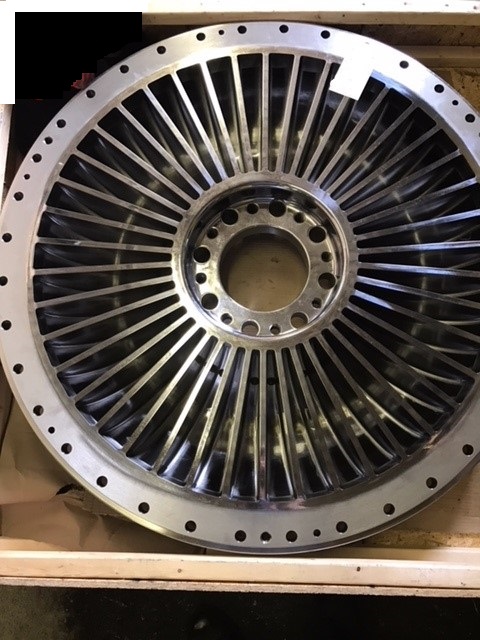

Our capabilities include close tolerance, high-speed machining across broad alloys. Our CNC milling department is networked with our CAD/CAM computer department to receive critical 3D programming and ensure quick, error-free transmission that results in defect-free finished products.

Our milling center includes a variety of precise, quality 3D machining centers, giving us the ability to machine exotic materials up to Rc 52. We serve various industries including, aerospace, automotive, power, railroad and more. Our production machining capabilities include:

- Castings

- Cavity Dies

- Fixtures

- Production

- Prototypes

- Secondary Tooling

CNC and VTL Contouring

With several numerical-controlled vertical and horizontal turning lathes, present in our Fraser, MI shop, we’re able to achieve superior contouring results on any project. Critical machining data is downloaded directly to our CNC contouring department via our CAD/CAM network. From there, our detailed CNC contour turning center has the ability to turn from under 1″ up to 70″ diameter, to an Rc 60.

Prototyping

From specialty and custom items and prototypes to production, we pride ourselves in a proven ability to achieve tight tolerances and micro-finishes. Our wide range of expertise includes products such as fixtures, shafts and cavity turns for clients in the industrial fields of aerospace, power, automotive and beyond.

Custom Solutions, Uncompromising Excellence

Whether it’s engineering or quality control, Reliable Forge Die & Engineering leans on ISO 9001:2015 Certified processes, and will design a customized program to meet your project’s unique needs. Contact us today at 586-296-5090 to discuss your needs for prototyping, seat and injection molds, die forging, and more.